GT55 Retrofit SFT

Predicting, growing demand in the automotive market and aerospace applications for noise reduction produced by a final drive gear set, GEI Systems has developed a family of computerized Single Flank Testers for this market to evaluate the TE in quality controlled environment.

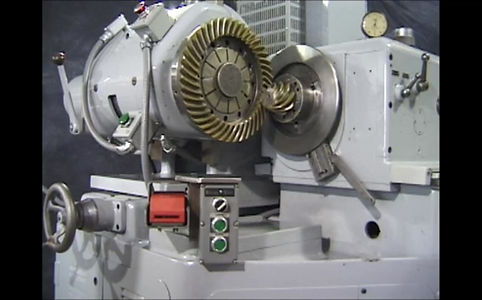

Single Flank Tester GT55, a retrofit version of the most common in industry manual tester Gleason 17A, has been developed as an alternative cost-effective solution to Gleason and Oerlikon equipment.

By design, GT55 combines the existing features from the original Gleason 17A unit, such as spindle tapers for both spindles, footprint and power requirements with high performance electronics, data acquisition, signal processing and motion control systems integrated into the unit as a part of retrofit process.

Using the original Gleason 17A unit, GEI has created a complete package and process to modify the spindle housings to install high accuracy optical encoders (similar to what has been used in new CNC models by Gleason and Oerlikon).

For a full-sized brochure

of the GT55 click below:

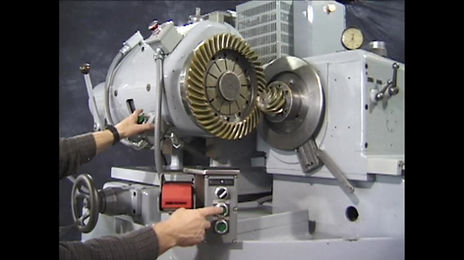

Switching from "Auto to Manual" mode to run a Conventional manual test

(see Brochure for details)

Running the entire TE test in "Auto" mode (drive side first, then coast side)

This is aeal time demonstration: 20 sec for the drive side , 20 sec for the coast and 10 sec between